Mon, Nov 11, 2024

[Archive]

Volume 15, Issue 4 (December 2018)

IJMSE 2018, 15(4): 62-69 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

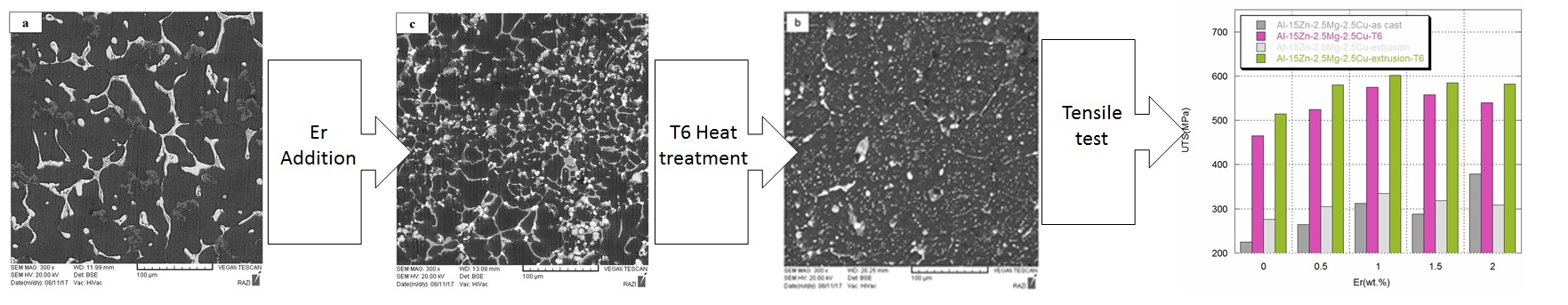

Kord S, Siadati M H, Alipour M, Amiri H, Koppad P, Gowda A C. Microstructure and Mechanical Behavior of As Cast and Hot Extruded AlZnMgCu Alloy with Rare Earth Erbium Additions. IJMSE 2018; 15 (4) :62-69

URL: http://ijmse.iust.ac.ir/article-1-1083-en.html

URL: http://ijmse.iust.ac.ir/article-1-1083-en.html

Abstract: (18018 Views)

The effects of rare earth element, erbium (Er) additions on the microstructure and mechanical properties of Al-15Zn-2.5Mg-2.5Cu alloy have been investigated. This new high strength alloy with erbium additions (0.5, 1.0, 1.5 and 2.0 wt%) was synthesized by liquid metallurgy route followed by hot extrusion. Microstructural characterization was performed using scanning electron microscope and electron probe microanalysis. Significant amount of grain refinement was observed with erbium addition in the hot extruded and heat treated alloy. Tensile test was performed to investigate the effect rare earth on mechanical behavior of alloy in as cast and hot extruded condition before and after T6 heat treatment. The combined effect of erbium addition, hot extrusion and heat treatment significantly enhanced the tensile strength of alloy (602 MPa) when compared to the as cast alloy without erbium addition (225 MPa). The strengthening of the alloy was attributed to grain refinement caused by erbium along with hot extrusion and formation of precipitates after T6 heat treatment. Fractograhic investigations revealed that the hot extruded alloy with erbium addition after heat treatment showed uniformly distributed deep dimples exhibiting ductile behavior.

Type of Study: Research Paper |

Subject:

Casting and Solidification

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |