Sat, Nov 9, 2024

[Archive]

Volume 20, Issue 1 (March 2023)

IJMSE 2023, 20(1): 1-18 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

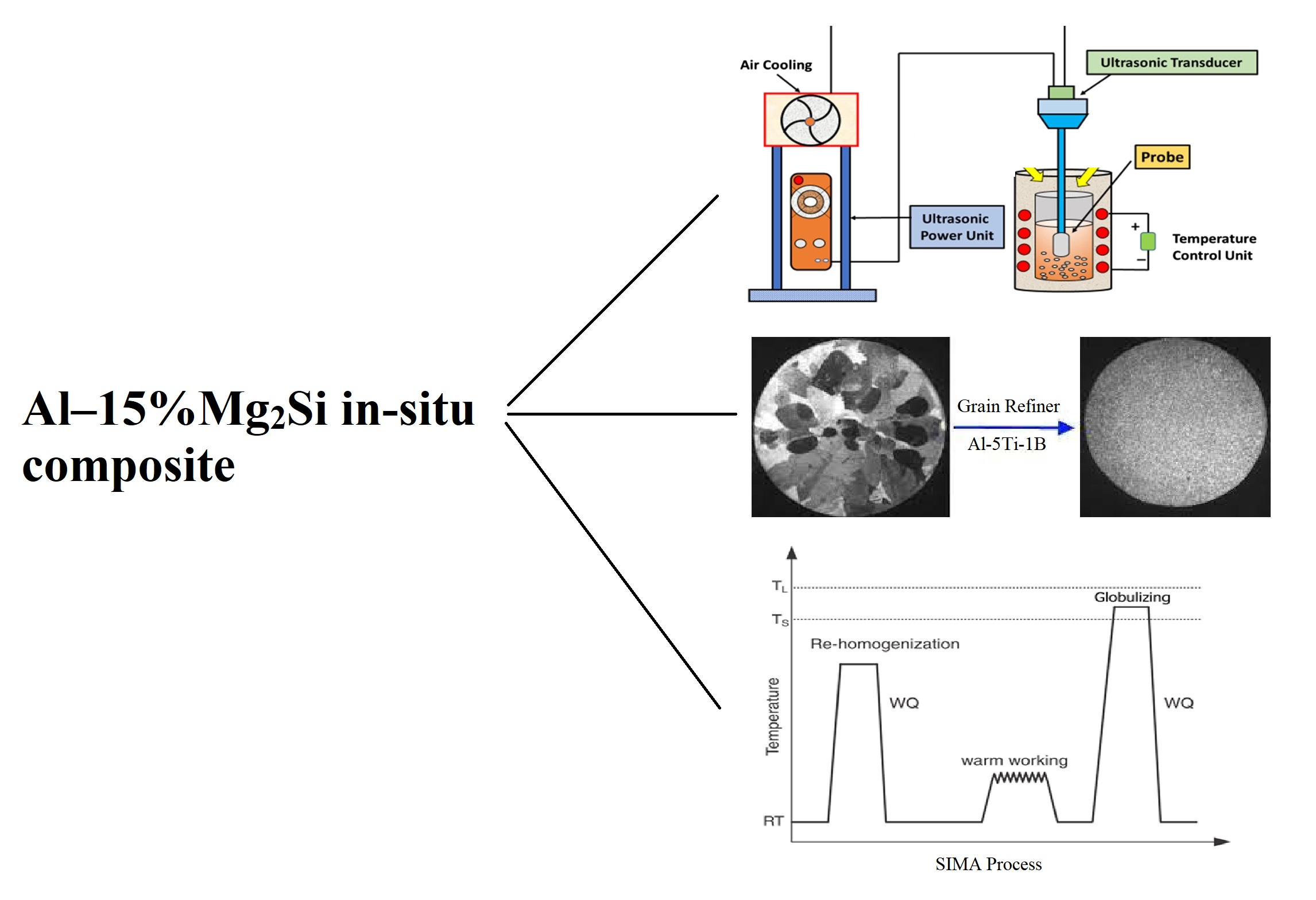

Alipour M. The Comparison of Effects of Ultrasonic Treatment, SIMA Process and Al-5Ti-1B Grain Refiner on the Microstructure and Mechanical Properties of Al–15%Mg2Si in-situ Composite. IJMSE 2023; 20 (1) :1-18

URL: http://ijmse.iust.ac.ir/article-1-2957-en.html

URL: http://ijmse.iust.ac.ir/article-1-2957-en.html

Abstract: (7133 Views)

The effect of Strain-Induced Melt-Activated (SIMA) Process, ultrasonic treatment (UST) and Al-5Ti-1B refiner on the microstructure and globularity of Al–15%Mg2Si composite was studied. Deformation of 25% were used. After deformation the samples were heated at 560, 580 and 595 °C for 5, 10, 20 and 40 min. The composite was treated with different amounts of the Ti concentrations and ultrasonic treatment with different power. Microstructural study was carried out on the alloy. It was observed that SIMA process, ultrasonic treatment and Al-5Ti-1B refiner has caused the globular morphology of Mg2Si particles. The results showed that for the desired microstructures of the alloy during SIMA process, the optimum temperature and time are 595 °C and 20 min respectively. Optimum amount of Ti refiner is 1 wt.% and power for UST is 1800W. After applying the SIMA process, Al-5Ti-1B master alloy and ultrasonic treatment, the strength and engagement have increased. This means that tensile strength increases from 251 MPa to 303 MPa and elongation percentage improves from 2.1 to 3.4, respectively.

Type of Study: Research Paper |

Subject:

Composites

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |