Wed, Dec 25, 2024

[Archive]

Volume 20, Issue 3 (September 2023)

IJMSE 2023, 20(3): 1-10 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

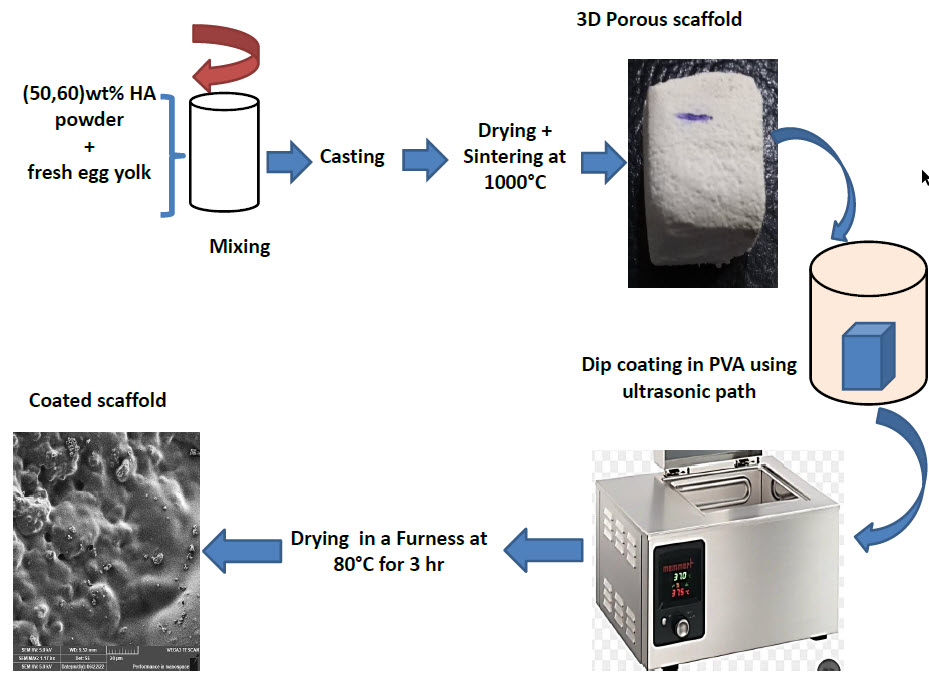

Sabree I K, Abd Aladel Jabar B. Fabrication of Porous Biologic Hydroxyapatite Scaffold Reinforced with Polymer Coating for Bone Tissue Engineering Candidate. IJMSE 2023; 20 (3) :1-10

URL: http://ijmse.iust.ac.ir/article-1-3118-en.html

URL: http://ijmse.iust.ac.ir/article-1-3118-en.html

Abstract: (8613 Views)

Abstract. Hydroxyapatite (HA) scaffold is commonly used in the applications of bone tissue engineering due to its bioactivity and equivalent chemical composition to the inorganic constituents of human bone. The present study focused on the fabrication of porous 3D hydroxyapatite scaffold which was modified by polymer coating as a successful strategy to improve the mechanical properties. A 3D porous hydroxyapatite scaffolds were fabricated by gel-casting method by using freshly extracted egg yolk (EY) with (50 and 60)wt% of HA powder. To enhance the mechanical properties, composite PVA / HA scaffolds were produced by using dip coating in Polyvinyl alcohol (PVA ). Fourier transform infrared spectroscopy (FTIR) was used to recognize the functional group associated with the hydroxyapatite scaffolds before and after PVA coating. The physical (density and porosity) and mechanical (compressive strength and elastic modulus) properties were investigated before and after coating. SEM was used to inspect the surface morphology and pore modification of the scaffolds. Wettability was determined by using a water contact angle to analyze the scaffold hydrophobicity. Surface roughness was studied by atomic force microscopy (AFM). It was revealed that the scaffold porosity decreased with increase solid loading of HA powder in the gel and after PVA coating. The findings showed that PVA coating improved mechanical strength of scaffold to be double by covering the small pores and filling microcracks sited on the scaffold strut surfaces, inducing a crack bridging mechanism. The scaffolds’ strength was in the range of trabecular bone strength. This indicates non-load bearing applications.

Type of Study: Research Paper |

Subject:

Synthesis and preparation of materials to meet the requirements of AM techniques

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |