BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

URL: http://ijmse.iust.ac.ir/article-1-864-en.html

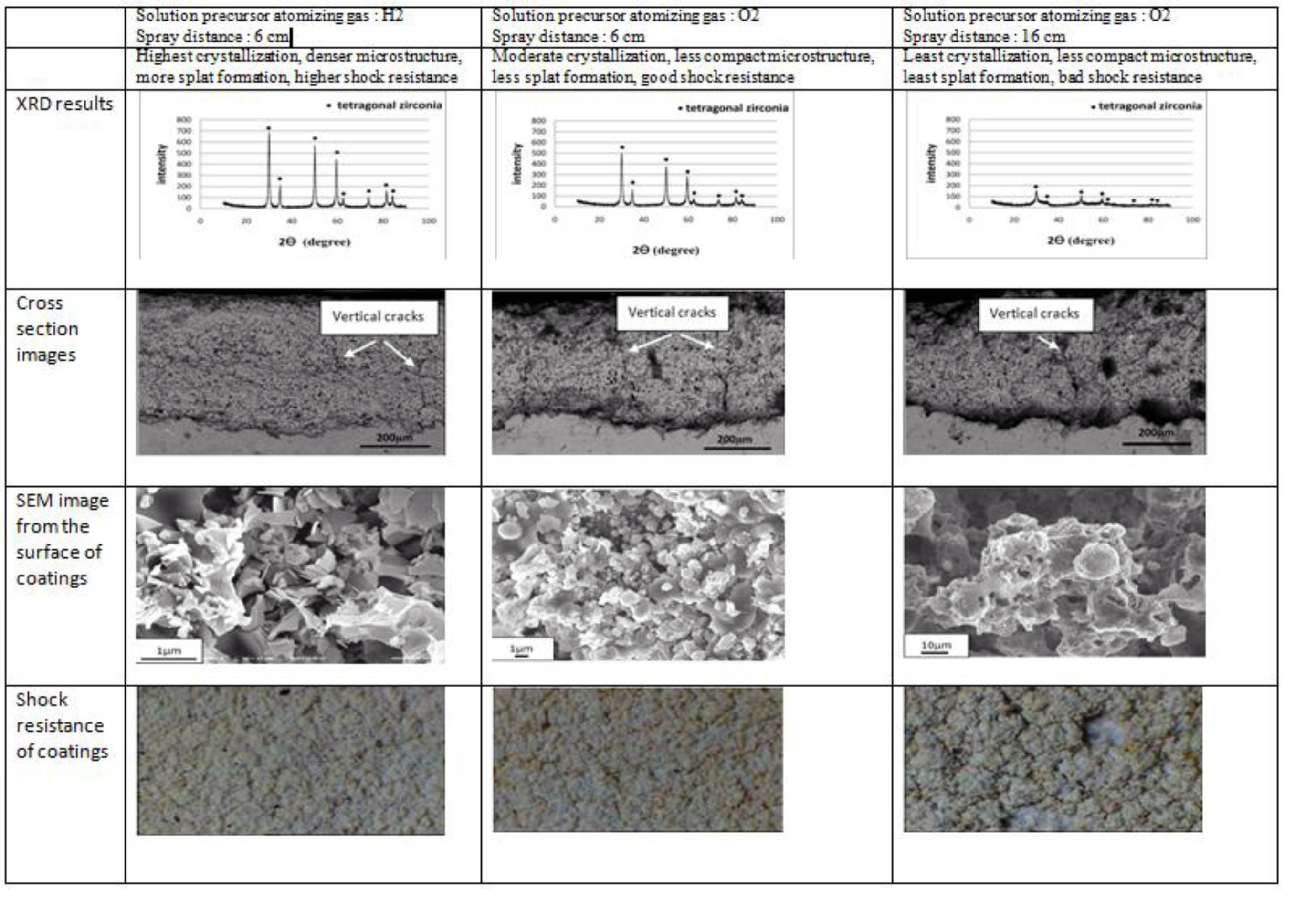

In this paper the effect of plasma spray parameters, atomizing gas and substrate preheat temperature on microstructure and phase composition of YSZ coatings produced by SPPS process have been investigated. The experimental results showed that increasing the power of plasma, using hydrogen as the precursor atomizing gas and increasing substrate preheat temperature decrease the amount of non-pyrolyzed precursor in the coatings. At low plasma power most of the deposited precursor is in non-pyrolyzed state, and consequently the applied coatings are defective. The increase in substrate temperature beyond 800oC either by preheating or heat transfer from plasma torch to the substrate, prevent the coating formation. In SPPS coating formation, up to a special spray distance the optical microscopy image of the coatings showed a snowy like appearance. XRD analysis showed that in this situation the amount of un-pyrolyzed precursor is low. Beyond this spray distance, spherical particles, are obtained and XRD analysis showed that most of the precursor is in un-pyrolyzed state.

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |