Fri, Nov 8, 2024

[Archive]

Volume 20, Issue 2 (June 2023)

IJMSE 2023, 20(2): 1-7 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

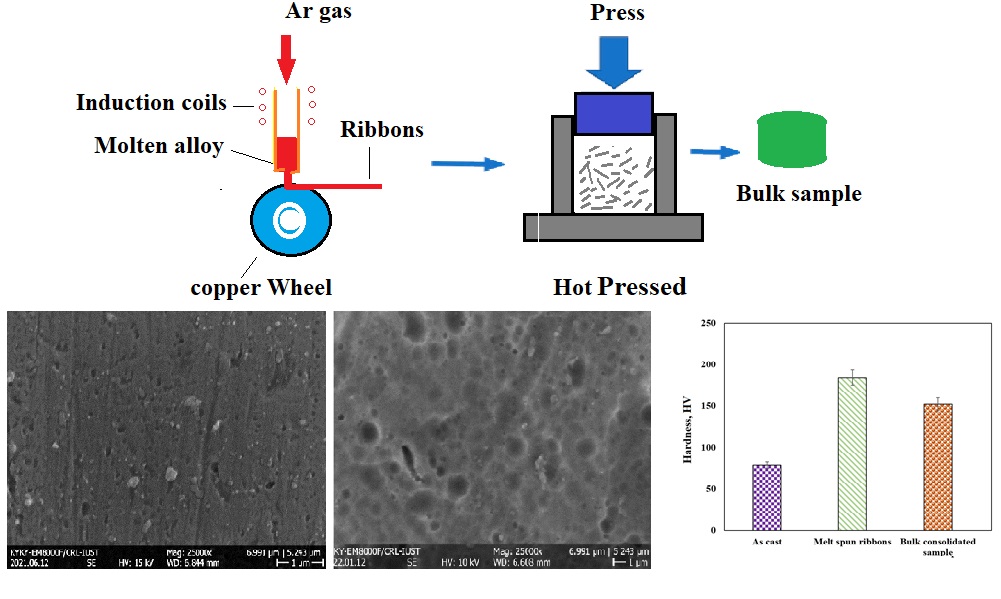

Salehi M, Dadashi M, Kashani Sani S P. The Effects of Rapid Solidification on the Microstructure and Mechanical Properties of Al5083. IJMSE 2023; 20 (2) :1-7

URL: http://ijmse.iust.ac.ir/article-1-3178-en.html

URL: http://ijmse.iust.ac.ir/article-1-3178-en.html

Abstract: (8531 Views)

In the present study, bulk refined-structured Al 5083 alloy with high mechanical properties was successfully fabricated by hot consolidation process of nanostructured melt- spun flakes. The influence of cooling rate and pressing conditions on the microstructure and mechanical properties of the alloy were investigated using X-ray diffractometer (XRD), optical microscopy (OM), field emission scanning electron microscopy (FE-SEM), microhardness, and compression tests. Rapid solidification combined with the hot consolidation at T=753 K (480 °C) and P= 800 MPa for 20 min produced a bulk sample with the desirable bonding, good microhardness (184.2±12.4 HV), and high strength (273±8 MPa) combined with 7 pct. fracture strain. These amounts are 78.6±5.1 HV, 148 ±9 MPa and about 5 pct. for the as-cast sample. Microstructural refinement during the controlled consolidation of nanostructure rapidly- solidified flakes contributes to such high mechanical properties of the bulk sample.

Keywords: rapid solidification, aluminum alloy 5083, mechanical properties, microstructure, hot consolidation

Type of Study: Research Paper |

Subject:

Composites

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |