Tue, Apr 8, 2025

[Archive]

Volume 20, Issue 3 (September 2023)

P. 1-10

P. 1-16

P. 1-11

P. 1-12

P. 1-10

P. 1-15

Fabio Edson Mariani

, Gabriel Viana Figueiredo

, Gabriel Viana Figueiredo

, German Barragan

, German Barragan

, Luiz Carlos Castelleti

, Luiz Carlos Castelleti

, Reginaldo Teixeira Coelho

, Reginaldo Teixeira Coelho

, Gabriel Viana Figueiredo

, Gabriel Viana Figueiredo

, German Barragan

, German Barragan

, Luiz Carlos Castelleti

, Luiz Carlos Castelleti

, Reginaldo Teixeira Coelho

, Reginaldo Teixeira Coelho

P. 1-10

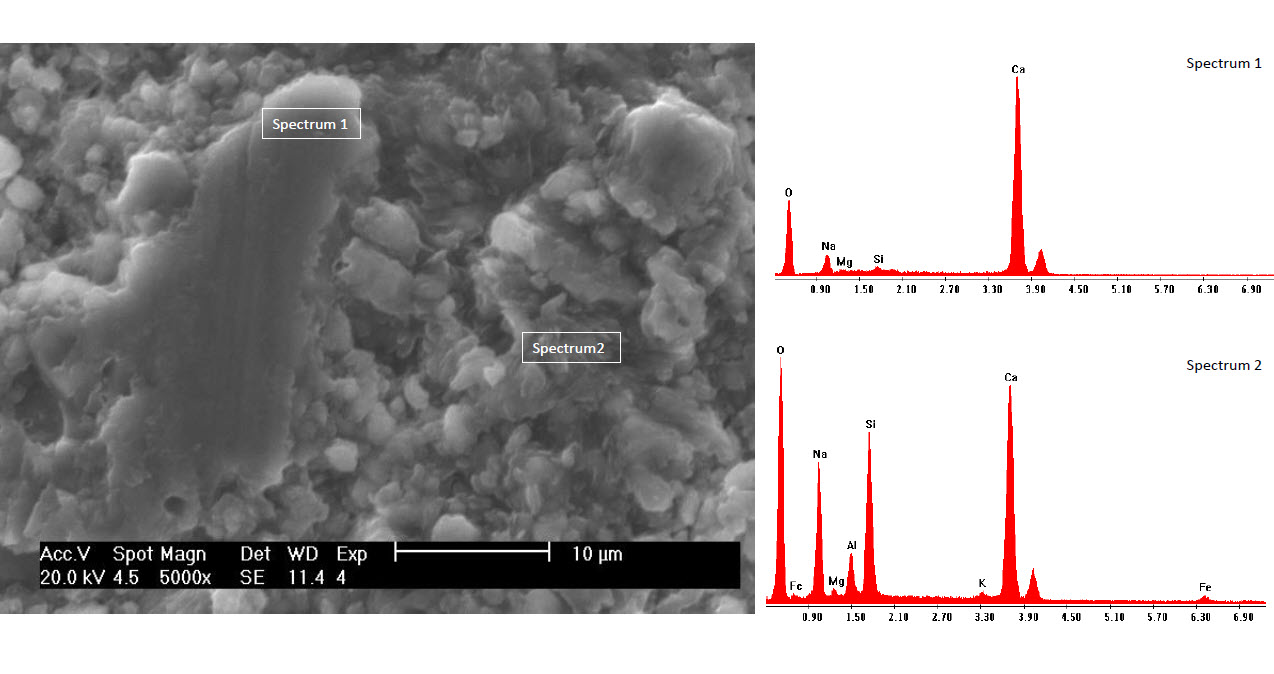

Ali Hasanzade Salmasi

, Mahban Zarei

, Mahban Zarei

, Shadab Safarzadeh Khosroshahi

, Shadab Safarzadeh Khosroshahi

, Soolmaz Heidari

, Soolmaz Heidari

, Farhood Najafi

, Farhood Najafi

, Mojtaba Ghomayshi

, Mojtaba Ghomayshi

, Katayoun Lesani

, Katayoun Lesani

, Mahban Zarei

, Mahban Zarei

, Shadab Safarzadeh Khosroshahi

, Shadab Safarzadeh Khosroshahi

, Soolmaz Heidari

, Soolmaz Heidari

, Farhood Najafi

, Farhood Najafi

, Mojtaba Ghomayshi

, Mojtaba Ghomayshi

, Katayoun Lesani

, Katayoun Lesani

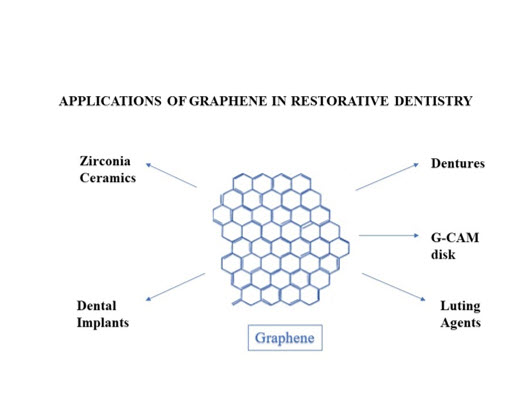

Hrishikesh Mahapatra

, Sumit Bedia

, Sumit Bedia

, Aishwarya Ramasubramanian

, Aishwarya Ramasubramanian

, Mridula Joshi

, Mridula Joshi

, Mahesh Ghadage

, Mahesh Ghadage

, Aarti Bedia

, Aarti Bedia

, Sumit Bedia

, Sumit Bedia

, Aishwarya Ramasubramanian

, Aishwarya Ramasubramanian

, Mridula Joshi

, Mridula Joshi

, Mahesh Ghadage

, Mahesh Ghadage

, Aarti Bedia

, Aarti Bedia

P. 1-7