Mon, Jan 27, 2025

[Archive]

Volume 21, Issue 2 (June 2024)

IJMSE 2024, 21(2): 118-131 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Zibanejad-rad A, Alizadeh A, Abbasi S M. A Comparison of Microstructure, Hardness, and Wear Behavior of Ti matrix Composites Reinforced with in-Situ Reinforcements Synthesized Using TiB2 and B4C. IJMSE 2024; 21 (2) :118-131

URL: http://ijmse.iust.ac.ir/article-1-3493-en.html

URL: http://ijmse.iust.ac.ir/article-1-3493-en.html

Abstract: (6606 Views)

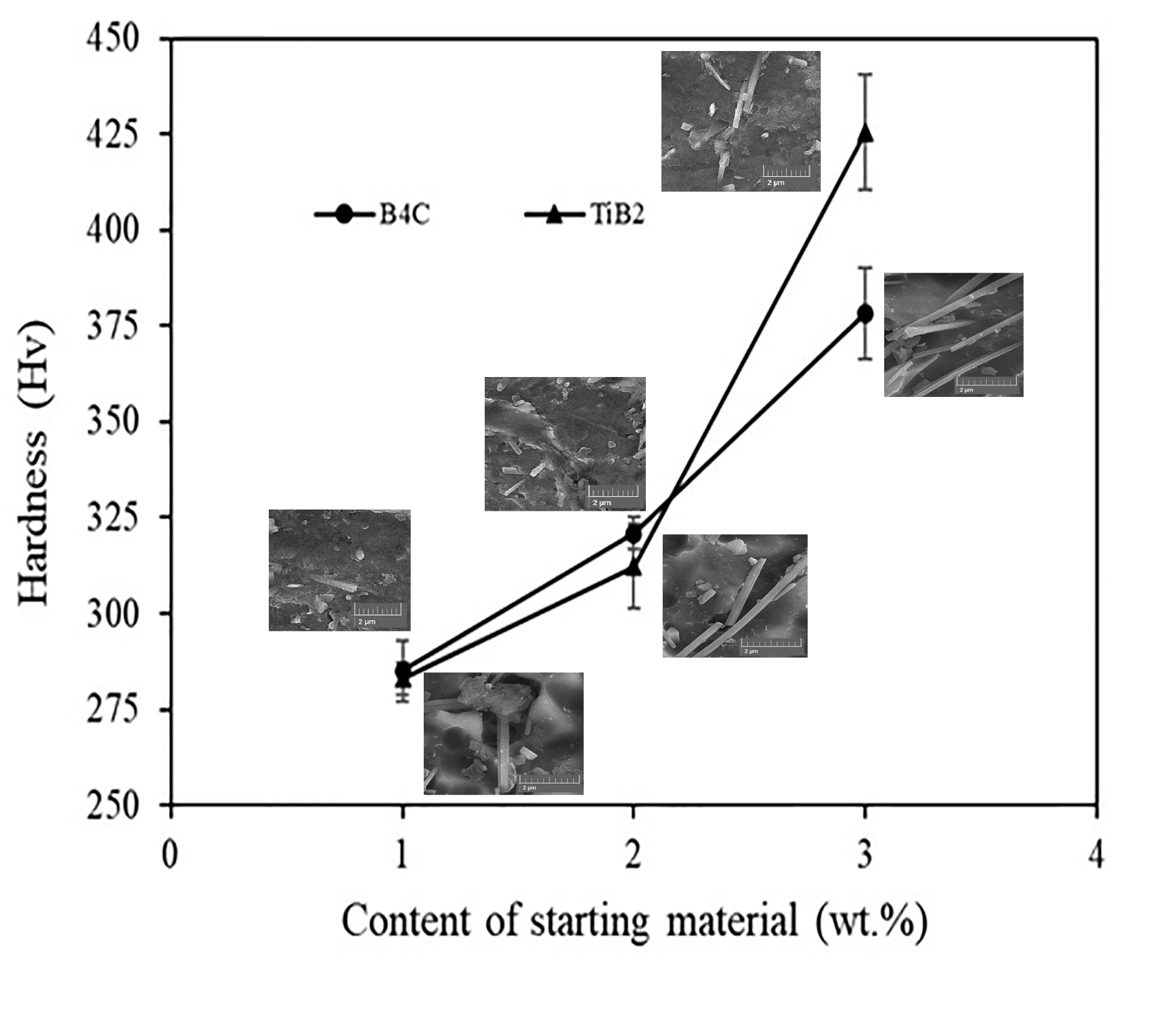

Pressureless sintering was employed at 1400 °C to synthesize Ti matrix composites (TMCs) reinforced with in-situ TiB and TiC reinforcements using TiB2 and B4C initial reinforcements. The microstructure and wear behavior of the synthesized composites were evaluated and compared and the results showed that B4C caused the formation of TiB-TiC in-situ hybrid reinforcements in the Ti matrix. Also, TiB was in the form of blades/needles and whiskers, and TiC was almost equiaxed. Moreover, the volume fraction of the in-situ formed reinforcement using B4C was much higher than that formed using TiB2. In addition, although the hardness of the B4C-synthesized composites was higher, the composite synthesized using 3 wt.% TiB2 exhibited the highest hardness (425 HV). The wear test results showed that the sample synthesized using 3 wt.% TiB2 showed the lowest wear rate at 50 N, mainly because of its higher hardness. The dominant wear mechanism in the samples synthesized using 3 wt.% B4C was abrasive and delamination at 50 N and 100 N, respectively while in the samples synthesized 3 wt.% TiB2, a combination of delamination and adhesive wear and adhesive wear was ruling, respectively.

Type of Study: Research Paper |

Subject:

Synthesis and preparation of materials to meet the requirements of AM techniques

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |